Welcome fellow makers and tech enthusiasts! You know me, always on the hunt for the next big thing that promises to revolutionize our workflows or simply bring a fresh wave of excitement to our hobbies. Today, we’re diving headfirst into the world of high-speed 3D printing with a machine that’s been making some serious noise (and printing parts even faster!): the Creality K1 3D Printer.

If you’re anything like me, you’ve probably been watching the evolution of 3D printing with a mix of awe and a healthy dose of skepticism. Promises of “blazing fast” speeds and “perfect prints” often fall short in reality. But the K1 rolls onto the scene with a bold declaration, aiming to deliver professional-grade speed and quality right to your desktop. Is this the game-changer we’ve been waiting for, or just another flashy contender? Let’s unpack everything there is to know about this intriguing machine.

Before we get too deep into the nitty-gritty, if the Creality K1 sparks your interest and you’re ready to jump into the future of fast 3D printing, you can grab yours and support this blog via my Amazon Associates link right here: https://amzn.to/44SazLY.

First Impressions: Unboxing the Speed Demon

The moment the Creality K1 arrives, its sleek, enclosed design immediately sets it apart from many open-frame FDM printers. It looks less like a hobbyist’s tinkering station and more like a serious piece of engineering equipment, ready for business. Unboxing reveals a mostly pre-assembled machine, a huge plus for anyone who’s spent hours wrestling with cryptic instructions and bags of unlabeled screws. Creality seems to be taking a page from the “it just works” playbook, aiming for a plug-and-play experience that gets you printing faster.

Initial setup largely involves removing protective packaging, installing the filament holder, and powering it up. The touchscreen interface is intuitive and responsive, guiding you through the first calibration steps. What immediately jumps out is the build quality; the frame feels robust, the enclosed chamber is well-sealed, and the overall aesthetic is clean and modern. It’s clear that Creality put thought into making this printer look and feel premium, even before you hit “print.”

Design & Ergonomics: A Enclosed Powerhouse

The Creality K1 boasts a fully enclosed build chamber, a design choice that offers multiple benefits. Firstly, it helps maintain a stable internal temperature, which is crucial for printing with advanced filaments like ABS, ASA, and Nylon, minimizing warping and improving layer adhesion. Secondly, it contributes to significantly quieter operation compared to open printers, making it a more agreeable addition to a home office or workshop. The enclosure also acts as a safety barrier, containing heat, fumes, and errant fingers – always a bonus when powerful machines are at play.

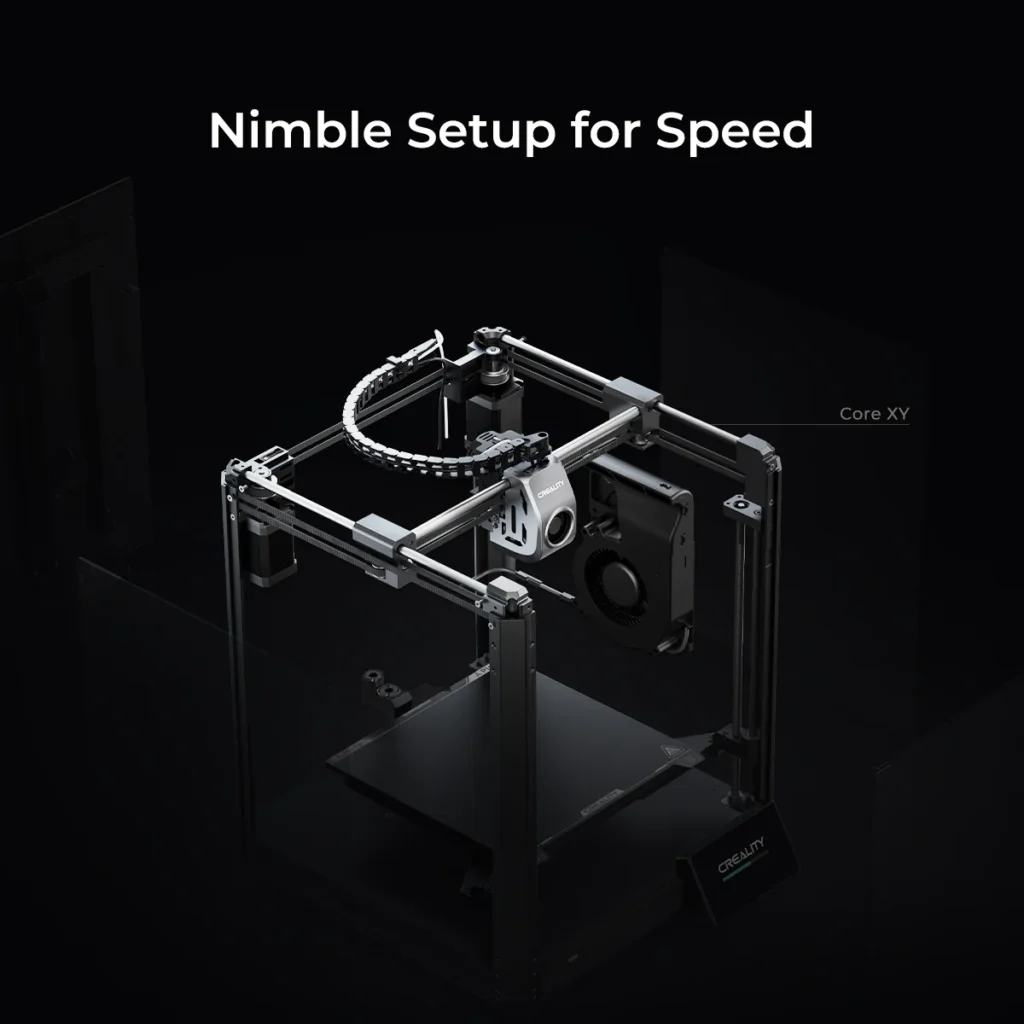

The CoreXY motion system is at the heart of the K1’s speed. This design allows for light moving parts and precise, rapid movements across the print bed, translating directly into faster print times without sacrificing accuracy. The direct drive extruder ensures excellent filament compatibility, handling everything from flexible TPUs to abrasive composites with ease, while the hotend is designed for high flow, necessary for pushing filament through at extreme speeds.

However, no design is without its quirks. The fully enclosed nature, while beneficial for some materials, can sometimes lead to overheating issues with standard PLA if not properly managed, requiring the top lid to be removed or the door to be slightly ajar for optimal results. Cable management, while neat internally, might require a bit of attention on the exterior to keep things tidy, especially with the rear-mounted filament holder. But these are minor points when weighed against the overall robust and thoughtful engineering.

Performance: Redefining Speed and Quality

Now, for the moment of truth: How does the Creality K1 actually perform? In a word: fast. Seriously fast. This printer isn’t just “quick for a desktop 3D printer”; it genuinely pushes the boundaries of what most users have come to expect from FDM technology. With acceleration speeds reaching up to 20000mm/s² and print speeds hitting 600mm/s (yes, you read that right!), the K1 is a true speed demon. What once took hours, or even a full day, can now be completed in a fraction of the time. This isn’t just about bragging rights; it fundamentally changes the way you approach projects, allowing for rapid prototyping, multiple iterations, and quicker turnarounds for production.

But speed without quality is just a fast mess. Thankfully, the K1 largely delivers on print quality too. The integrated G-sensor for auto-leveling and input shaping plays a crucial role here, minimizing vibrations and ensuring smooth, consistent layers even at high velocities. Reviewers consistently highlight impressive surface finishes and dimensional accuracy, especially when using Creality’s optimized filament profiles. While out-of-the-box prints are often excellent, a bit of fine-tuning can elevate them to near-perfection, a common theme in the 3D printing world.

However, the pursuit of speed can sometimes expose minor weaknesses. Some users report that achieving consistent high-quality prints at the absolute maximum speeds requires careful calibration and sometimes a slight reduction from the advertised 600mm/s. The cooling system, while effective, can occasionally struggle with very small, intricate details on overhangs when pushed to its limits. Yet, even with these minor caveats, the K1’s performance is a significant leap forward, making it a compelling choice for anyone prioritizing rapid output without sacrificing acceptable quality. For more in-depth analyses of its speed capabilities, I highly recommend checking out independent tests on YouTube channels like Printables.com or various 3D printing communities on Reddit.

Value for Money: A Competitive Edge

When evaluating the Creality K1, its price point positions it firmly in the competitive “prosumer” segment of the 3D printer market. However, when you factor in its enclosed design, CoreXY kinematics, direct drive extruder, high-speed capabilities, and automated features like auto-leveling, it presents an undeniably strong value proposition. Many printers with comparable features and speeds come with a significantly higher price tag.

The time-saving aspect of the K1’s speed also translates directly into value. For hobbyists, it means more completed projects and less waiting. For small businesses or those using 3D printing for rapid prototyping, the ability to iterate faster can save substantial costs and accelerate development cycles. The inclusion of a robust build volume and compatibility with a wide range of filaments further enhances its versatility, ensuring you get more bang for your buck across diverse printing needs.

While initial investment might seem higher than entry-level machines, the reduced print failures (thanks to the enclosed chamber and precise motion) and the sheer acceleration in project completion often offset this cost very quickly. For those upgrading from slower, less reliable open-frame printers, the Creality K1 offers a significant leap in efficiency and capability without breaking the bank. Don’t just take my word for it; compare its specs and features against other high-speed FDM printers on the market, and you’ll quickly see the compelling value.

Ease of Use: Beyond the Unboxing

Creality has made significant strides in making the K1 user-friendly, a welcome change for a machine capable of such advanced performance. As mentioned, the out-of-the-box experience is streamlined, reducing the typical frustration associated with 3D printer assembly. The intuitive touchscreen interface guides users through essential operations, making tasks like loading filament, initiating prints, and monitoring progress straightforward.

The automated bed leveling system (a feature becoming increasingly standard on higher-end machines but still a highlight here) drastically simplifies the often-dreaded manual calibration process. For beginners, this means less time troubleshooting and more time creating. For experienced users, it’s a welcome convenience that saves valuable minutes. The integrated camera (on some models) and remote printing capabilities via Creality Cloud or other network solutions add to the overall convenience, allowing you to manage prints from anywhere.

However, embracing high-speed printing does come with a learning curve that goes beyond the printer itself. While the K1 simplifies the hardware, maximizing its speed potential often requires an understanding of advanced slicer settings, specialized high-flow filaments, and occasional tweaks to achieve optimal results. Community support is strong, with an active user base sharing tips and tricks, but be prepared to occasionally delve into forums or YouTube tutorials to fully unlock its potential. For most users, the balance between powerful features and ease of operation is well-struck, making the Creality K1 an accessible entry point into the world of truly fast 3D printing.

Pros and Cons: A Quick Snapshot

Let’s sum up the key strengths and areas for improvement for the Creality K1 3D Printer:

- Blazing Fast Print Speeds: Capable of speeds up to 600mm/s, significantly reducing print times.

- Robust CoreXY System: Ensures stability and precision, even at high velocities.

- Fully Enclosed Build Chamber: Ideal for printing high-temperature filaments like ABS and ASA, reducing warping.

- Direct Drive Extruder: Excellent filament compatibility, including flexible materials.

- User-Friendly Interface: Intuitive touchscreen and largely plug-and-play setup.

- Automated Calibration: G-sensor auto-leveling and input shaping simplify setup and improve print quality.

- Solid Build Quality: Feels sturdy and well-engineered.

- Competitive Price Point: Offers advanced features typically found in more expensive machines.

Cons:

- Potential for PLA Overheating: Enclosed chamber might require lid removal for PLA to prevent heat creep.

- Initial Slicer Learning Curve: Achieving optimal high-speed prints often demands deeper knowledge of slicer settings.

- Cooling Limitations on Fine Details: Can sometimes struggle with very small, intricate overhangs when pushed to its limits.

- External Filament Holder: While functional, it’s outside the enclosure, which might not be ideal for some hygroscopic filaments without additional solutions.

The Verdict: Is the Creality K1 Your Next 3D Printer?

The Creality K1 3D Printer truly stands out as a compelling option in the rapidly evolving 3D printing landscape. It delivers on its promise of high-speed printing without compromising significantly on quality, making it a fantastic choice for both hobbyists looking to accelerate their projects and professionals needing rapid prototyping capabilities. The thoughtful enclosed design, robust kinematics, and user-friendly features make it a joy to operate, especially for those ready to move beyond entry-level machines.

While it has a few minor quirks, primarily around optimizing for specific filaments at extreme speeds, these are easily manageable with a little community-sourced knowledge and experimentation. If you’re tired of long print times and are eager to experience the next generation of FDM 3D printing, the Creality K1 offers an exceptional balance of performance, features, and value.

Don’t wait to bring the future of fast, reliable 3D printing to your workshop. The Creality K1 3D Printer is a machine that will transform your printing experience, freeing up time for more design, more iteration, and more creative exploration.

Ready to unlock unparalleled speed and precision in your 3D printing journey? Get your Creality K1 3D Printer today: https://amzn.to/44SazLY

Happy Printing!